Our safety innovations

We’re using the latest technology to ensure our operatives are exposed to the minimum of safety risks.

Health and safety by design

3D Visual Design

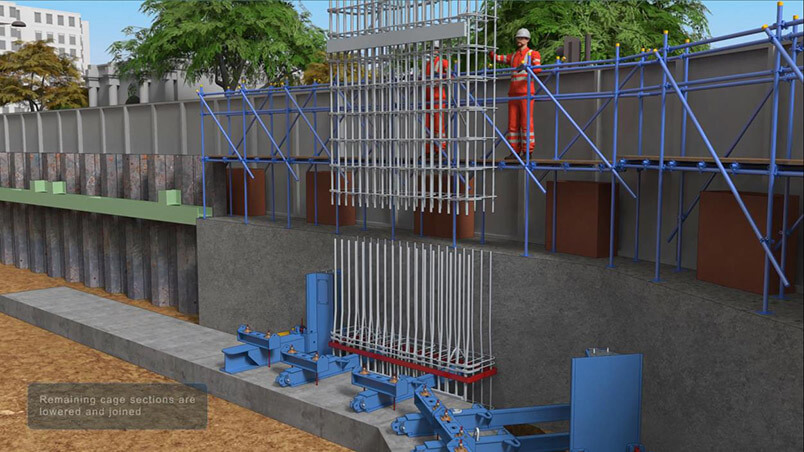

Using 3D and 4D computer models that are produced by our in-house Visual Design team, Balfour Beatty Investment Holdings Ltd's project teams are able to test processes and procedures in the virtual world before doing things for real. The computer models can work as both a simulation of the site conditions and as a training tool for site operatives to preview and understand a complex construction procedure.

1. Here's an example 3D model that used to develop a design and procedure:

2. Here's the real-world installation:

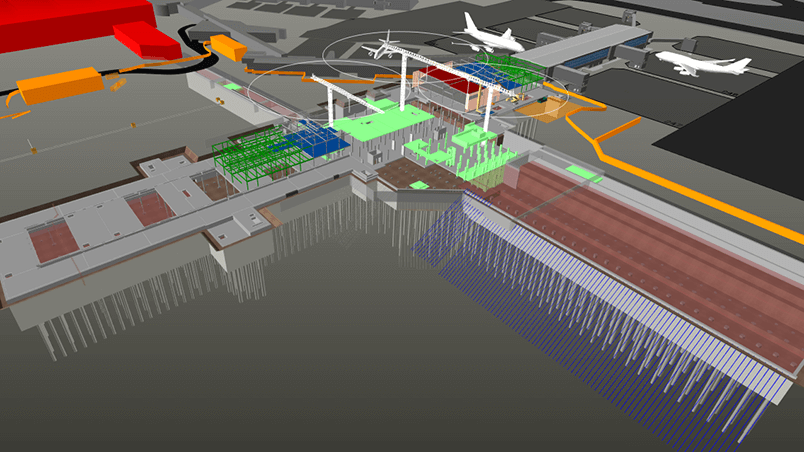

BIM (Building Information Modelling)

Utilising 3D modelling software, it is possible to identify potential clashes between services and disciplines on a project and make alterations to the design. Potential safety risks can be spotted in advance using the models.

4D modelling takes things a step further and plots the different construction phases against a timeline. This can be used to ensure the various phases of a project are not going to delay each other or cause each other safety risks when construction begins.

25% by 2025 - Modular and off-site pre-fabricated construction

While many companies are beginning to consider off-site and modularisation on a case-by-case basis for new schemes, Balfour Beatty Investment Holdings Ltd has made it a core part of our strategy. We have committed to reducing onsite activity by 25% by 2025.

Supporting the Government’s 2025 strategy for lower cost, lower emissions and faster delivery, we aim to remove those activities we can from sites in order to free up our workforce’s time to focus on delivery.

This gives us the scope to create complex structures safely and efficiently offsite, assembling them quickly onsite. It not only saves time, but also reduces costs, improving overall efficiency compared with traditional methods of construction.

Our Off-site Solutions facility can prefabricate entire mechanical and engineering modular units, ready for connection into the mains services, eliminating the need for operatives to enter a riser shafts at height during construction. It also improves working conditions for the workforce and reduces the need for hot works and electrical works on a site environment.

Innovative methods of construction

At Whitechapel Station, we used an innovative, arched concrete wailing-wall cast into the diaphragm wall at the point of support.

It was possible to reduce the number of props used to support the structure which reduced the chance of the props being struck during the works.

Planning ahead

Precast ‘unistrut’ rods can be cast directly into the above concrete floor slab. This enables the vertical supporting rods to hold the ducts and cable trays without requiring any further drilling. This in turn leads to an estimated 75% reduction in working at height and eliminates much of the the unwanted dust, vibration and access problems.

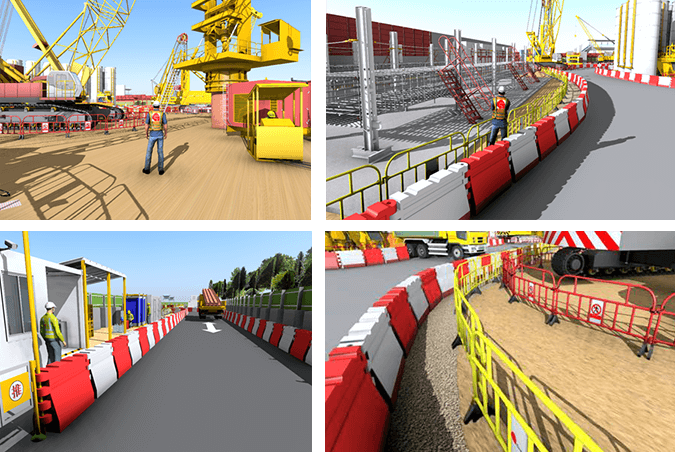

Virtual Reality (VR) for off-site safety training

We’re working with key partners to develop VR experiences that improve safety onsite. For example, alongside our joint venture partner Vinci we are creating VR simulators in a bid to boost safety standards on our Smart Motorway sites.

We’ve already created fully immersive simulations, designed to prevent on-site accidents through improved training. Using a VR headset, the user experiences real-world scenarios that give different perspectives of a potentially dangerous situation. This allows them to develop an understanding of safe working zones without the need to be on site, removing them from any potential risks (and allowing them to experience failure in a safe environment) until the training is complete.

We have created simulations for people-plant interface, temporary works for form-work and excavations, concrete environments and welding.

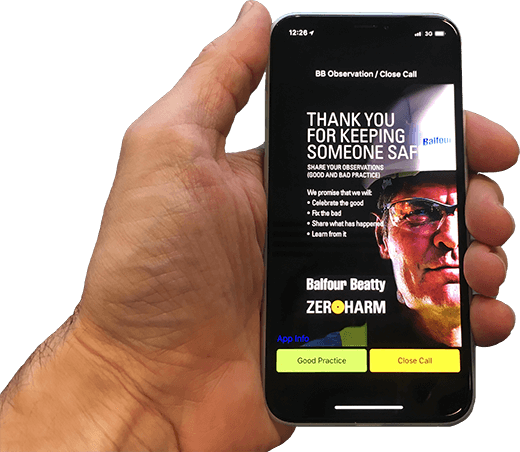

Smartphone Observation App

We encourage the use of smart devices to report good and bad practices across our sites. We’ve developed our own ‘Balfour Beatty Investment Holdings Ltd Observations’ app to allow our employees and contractors to report their observations of close calls and share best practice.

The app provides an easy, anonymous method of reporting near misses in real time. It records the exact location of the reporter and captures photographic evidence of the incident.

It can be used to simplify near miss reporting and enable a greater understanding of the incident through the provision of photographic evidence.

What comes next?

Balfour Beatty Investment Holdings Ltd is already working with many new technologies which could have a safety impact. These include wearable technologies, use of robotics, plant automation, off-site prefabrication, augmented reality and 'virtually there' technology as we look for new ways to reduce the risks to our workforce. Check back soon to see further updates to this page as these new ideas are embedded on our sites.

You can read about how we got to where we are today and what the future of construction might look like on Our safety timeline page.